West Virginia High-Risk Jobs with Exposure to Engineered Stone Silica Dust

Workers in West Virginia high-risk jobs with exposure to engineered stone silica dust face serious health risks from tasks such as cutting, grinding, and polishing engineered stone. These activities release fine crystalline silica particles into the air, increasing the risk of developing silicosis, a severe and irreversible lung disease. Without proper safety precautions, industries like countertop fabrication and construction continue to endanger workers’ respiratory health.

High-Risk Occupations in West Virginia Linked to Silica Dust Exposure

In West Virginia, certain occupations are at a heightened risk of exposure to silica dust, particularly in industries involving engineered stone and related materials. Below are some of the most high-risk jobs in the state:

- Countertop fabricators: Workers in this field cut, shape, and polish engineered stone for countertops. These activities generate silica dust, which can linger in the air and be inhaled. Without proper safety protocols, such as wet-cutting and ventilation systems, fabricators face severe risks of silicosis and other respiratory illnesses.

- Construction workers: Construction professionals in West Virginia handle engineered stone and other silica-containing materials in building projects. Tasks like drilling, sanding, and demolition release silica dust, which can accumulate in poorly ventilated workspaces. This industry is one of the most hazardous when it comes to prolonged silica exposure.

- Coal miners: West Virginia’s mining industry remains a cornerstone of its economy, but miners often encounter silica dust when cutting through sandstone or granite. Prolonged exposure can lead to a combination of silicosis and coal workers’ pneumoconiosis, compounding respiratory health issues.

- Masons and stonecutters: Masons and stonecutters in the state work extensively with engineered stone and masonry materials, which are rich in crystalline silica. Activities like cutting, grinding, and installing stonework create airborne dust that can severely harm workers’ lungs over time.

- Sandblasters: Sandblasters use high-pressure equipment to clean surfaces, often with silica-containing abrasive materials. This process generates large amounts of silica dust, putting workers at extreme risk without proper respiratory protection and containment measures.

- Quarry workers: Quarrying activities, such as extracting raw materials for construction and engineered stone production, expose workers to high levels of silica dust. These workers often operate heavy machinery in dusty environments, leading to sustained exposure if safety controls are inadequate.

Workers in these fields often perform tasks that release fine crystalline silica particles into the air, which can pose significant health risks when protective measures are not in place. Prolonged exposure to silica can lead to a serious and potentially life-threatening disease called silicosis.

Health Risks of Engineered Stone Silica Dust Exposure

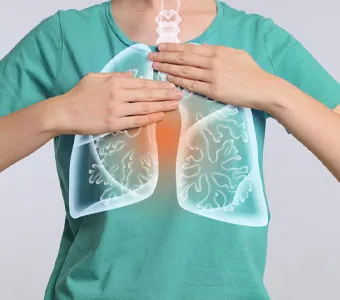

Exposure to engineered stone silica dust poses severe health risks, especially for workers in high-risk occupations. Silicosis, an incurable lung disease, is one of the most prevalent conditions resulting from prolonged silica exposure. This disease develops when silica particles are inhaled and cause scarring in the lungs, reducing their ability to function effectively.

Other health risks associated with silica dust exposure include:

- Chronic Obstructive Pulmonary Disease (COPD): Long-term silica exposure can lead to chronic airway inflammation and reduced lung capacity, significantly affecting workers’ quality of life.

- Lung Cancer: Classified as a human carcinogen, crystalline silica exposure increases the likelihood of developing lung cancer, particularly among workers with extended exposure.

- Kidney Disease: Research has linked silica exposure to an increased risk of kidney damage and chronic kidney disease, further impacting workers’ overall health.

Exposure to silica dust remains a preventable hazard when proper safety measures are implemented. Protecting workers requires strict adherence to OSHA standards and proactive workplace controls to minimize the risk of long-term health consequences.

FAQs

Q: What Is the OSHA Rule for Silica Dust?

A: OSHA has established strict regulations to limit workplace exposure to silica dust. This rule requires employers to implement control measures, such as wet-cutting techniques and air filtration systems, to reduce silica dust levels. Employers must conduct regular exposure assessments, provide protective equipment, and offer medical monitoring for workers in high-risk industries to avoid violating these regulations.

Q: What Occupations Are Exposed to Dust?

A: Occupations exposed to silica dust include engineered stone fabricators, construction workers, sandblasters, concrete polishers, and quarry workers. These roles often involve tasks like cutting, grinding, or drilling materials that contain crystalline silica. Without proper safety protocols, workers in these industries face increased risks of respiratory conditions, including silicosis, due to prolonged exposure to hazardous dust.

Q: What Are the Symptoms of Silica Dust Exposure?

A: Symptoms of silica dust exposure include persistent coughing, shortness of breath, chest pain, and fatigue. Over time, prolonged exposure can lead to more severe conditions like silicosis, which may cause difficulty breathing, weight loss, and respiratory failure. Early detection and medical intervention are critical to managing these symptoms and preventing long-term health complications.

Q: What Is the Maximum Workplace Exposure to Silica Dust?

A: OSHA’s permissible exposure limit (PEL) for respirable crystalline silica is 50 micrograms per cubic meter of air, averaged over an eight-hour workday. This standard aims to minimize workers’ exposure and reduce the risk of silica-related illnesses. Employers are required to monitor air quality, implement control measures, and provide proper respiratory protection to ensure compliance with these limits.

Q: How Can Employers Protect Workers from Silica Dust Exposure?

A: Employers can protect workers by implementing safety measures such as using wet-cutting techniques, improving ventilation systems, and providing respiratory protection. Regular air monitoring and training on silica hazards are also required to ensure compliance with OSHA standards. By adopting these precautions, employers can significantly reduce the risk of silica dust exposure and safeguard workers’ health in high-risk industries.

Schedule Your Exposure to Engineered Stone Silica Dust Consultation Today

Exposure to silica dust from engineered stone poses significant health risks, including the development of silicosis, a serious and irreversible lung disease. If you or someone you love has been impacted by unsafe workplace conditions, seeking legal representation is critical. A skilled attorney can help you navigate your options and pursue compensation for medical costs, lost wages, and other damages caused by silica dust exposure.

At Wallace & Graham, P.A., we are dedicated to helping workers and families affected by engineered stone silica dust exposure. Our team works tirelessly to build strong cases and secure justice for those harmed by negligence. Schedule your consultation today to discuss your situation and learn how we can support you in seeking the recovery you deserve.