How Are Engineered Stone Companies Addressing Silicosis Concerns?

As awareness of the dangers of silicosis grows, how are engineered stone companies addressing silicosis concerns? Many companies in the engineered stone industry are taking steps to reduce the risks associated with crystalline silica exposure. These efforts include implementing safety measures such as using wet-cutting methods to minimize dust, providing personal protective equipment (PPE) like respirators, and improving ventilation systems in fabrication shops.

Recent Concerns Over Silicosis in Engineered Stone Manufacturing

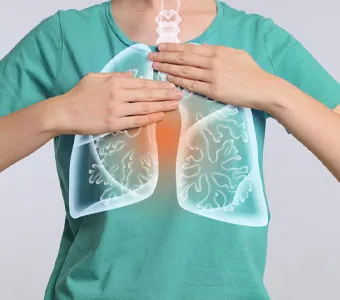

Silicosis, a lung disease caused by inhaling crystalline silica dust, has raised significant concerns within the engineered stone industry. Recent reports show a sharp rise in cases, especially among workers involved in fabricating countertops and stone surfaces.

Engineered stone, which contains high levels of silica, is particularly hazardous when it’s cut, ground, or polished without proper safety precautions. As the industry grows, exposure to silica dust has become a major public health issue, with workers at high risk of developing this debilitating disease.

In response, the U.S. and other countries have raised alarms, urging manufacturers to take stronger action to protect workers. Increased awareness of silicosis has spurred calls for better safety standards, stricter enforcement, and safer alternatives in stone production.

Enforcement Measures and Regulatory Responses to Silica Dust Exposure

The growing concern surrounding silica dust exposure has led to stricter enforcement measures from government agencies. The U.S. Occupational Safety and Health Administration (OSHA) has ramped up its inspections and enforcement of regulations aimed at minimizing silica exposure in high-risk industries, including engineered stone manufacturing.

This shift comes as part of an ongoing effort to protect workers from silicosis and other respiratory diseases. Similarly, California has recently adopted a permanent silica safety standard for artificial stone workers, highlighting the state’s commitment to regulating this dangerous exposure more rigorously.

These actions signal a broader shift toward stricter oversight, requiring companies to comply with dust control measures and implement effective safety protocols. Companies producing engineered stone now face increased scrutiny and potential penalties for non-compliance.

Industry-Wide Efforts to Address Silicosis Concerns

In response to the growing concerns over silicosis, many companies in the engineered stone industry have started to adopt more protective practices to protect their workers. One such initiative includes the implementation of wet-cutting techniques and advanced ventilation systems designed to minimize the amount of dust created during stone fabrication.

Some manufacturers have begun switching to alternative materials with lower silica content to reduce exposure risks. These proactive steps are part of the broader push toward creating a safer working environment and addressing the health risks associated with silica dust.

However, many people argue that these efforts need to be strictly and universally enforced to prevent silicosis. Industry leaders are recognizing the importance of addressing these risks not just for the safety of workers but also to avoid potential legal challenges down the road.

The Financial and Legal Implications for Engineered Stone Companies

The ongoing scrutiny of silica dust exposure has major financial and legal implications for engineered stone companies. As the government tightens regulations and increases inspections, manufacturers are facing higher costs associated with compliance.

These include investments in safety equipment, employee training, and potential upgrades to factory ventilation systems. In addition, companies must contend with the risk of legal action from workers suffering from silicosis.

The rising number of claims related to silicosis and other lung diseases poses significant financial liability for companies that fail to implement effective safety measures. In some cases, businesses are also facing increased insurance premiums due to the prevalence of high silica exposure risks.

FAQs

Q: What Can Help Eliminate the Risk of Silicosis in These Workers?

A: To reduce and eliminate the risk of silicosis, employers must implement safety measures like wet-cutting methods, ventilation systems, and dust suppression equipment. Workers should wear proper PPE, including P100 or N100 respirators, to minimize exposure. Regular health monitoring and training are also crucial to ensure safety. These precautions significantly reduce the risk of silica dust inhalation and help protect workers’ long-term health.

Q: Does Engineered Stone Cause Silicosis?

A: Yes, engineered stone can cause silicosis due to its high silica content. During the cutting, grinding, or polishing of engineered stone countertops, respirable silica dust is released. Prolonged exposure to this dust can cause silicosis, a serious lung disease. Workers involved in these activities are at a heightened risk of developing the disease, especially if protective measures such as respirators and ventilation are not in place.

Q: Is Silicosis a Problem in the Construction Industry?

A: Yes, silicosis is a significant problem in the construction industry. Workers involved in tasks like stone cutting, demolition, and masonry are often exposed to silica dust, which can lead to silicosis. Prolonged exposure to crystalline silica dust common in construction materials like concrete, granite, and engineered stone increases the risk of developing this serious lung disease if proper safety measures aren’t followed.

Q: Is Engineered Stone a Health Hazard?

A: Yes, engineered stone can be a health hazard due to its high silica content. Workers who cut, grind, or polish engineered stone countertops are exposed to respirable silica dust, which can cause silicosis, lung disease, and other respiratory conditions. The lack of proper protective measures like respirators and dust control systems can significantly increase the risk of health problems for workers in the stone fabrication industry.

Q: What Are the Long-Term Effects of Silicosis on Engineered Stone Workers?

A: The long-term effects of silicosis in workers exposed to engineered stone dust can be devastating. Over time, silica particles trapped in the lungs cause scarring, leading to progressive breathing difficulties. Workers with severe silicosis may experience chronic respiratory failure, require oxygen assistance, and face an increased risk of lung cancer, tuberculosis, and other respiratory diseases. Advanced silicosis can severely impair quality of life and can be fatal if left untreated.

Schedule Your Silicosis Consultation Today

If you or a loved one has been exposed to silica dust and are dealing with the devastating effects of silicosis, it’s crucial to understand your rights. Silicosis is a preventable but severe disease caused by prolonged exposure to respirable crystalline silica, often occurring in industries like construction and stone fabrication. At Wallace & Graham, we are committed to helping victims of silicosis navigate the complex legal process and secure the compensation they deserve.

Our experienced legal team can guide you through every step of your case, ensuring that your medical expenses, lost wages, and other damages are accounted for. With a deep understanding of the laws surrounding silicosis claims, Wallace & Graham can help you fight for justice and compensation. Contact our legal team today to schedule your consultation and start your journey toward securing the support you need.